How to 3D Print Multicolor Models: A Comprehensive Guide

Creating multicolor 3D prints is one of the most exciting advancements in 3D printing. It transforms ordinary projects into visually stunning creations. Whether you’re crafting figurines, architectural models, or prototypes, the ability to incorporate multiple colors can add a professional and artistic touch. This guide explores various methods, technologies, and tips for printing multicolor models, focusing on techniques that work well with the best 3D printer.

Understanding Multicolor 3D Printing

Multicolor 3D printing refers to producing objects with more than one color, either for aesthetic or functional purposes. This can be achieved through various techniques and tools, depending on your printer’s capabilities and the desired complexity of your project.

Some popular methods include:

- Filament Swapping: Manually or automatically changing the filament during the print.

- Dual Extrusion Printing: Using two extruders for simultaneous printing with different colors.

- Filament Mixing Printers: Combining filaments during printing to create custom gradients or colors.

- Painting Post-Printing: Adding color manually after the print is complete.

Techniques for Printing Multicolor Models

1. Filament Swapping

Filament swapping is the most straightforward method and requires minimal additional hardware.

- How it works: Pause your printer at specific layers and manually change the filament to a different color. Resume the print to layer the new color.

- Advantages: Works with almost any 3D printer. Cost-effective for simple color transitions.

- Challenges: Labor-intensive for complex models. Accuracy depends on timing and manual execution.

2. Dual Extrusion Printing

Dual extrusion is a popular method supported by some of the best 3D printers.

- How it works: The printer has two extruders, each loaded with a different filament. Both extruders work in tandem to print parts of the model in different colors.

- Advantages: Fully automated process. Allows for intricate, multi-color designs. Can combine different material types (e.g., PLA and PVA for supports).

- Challenges: Requires careful calibration to avoid nozzle clashes or misalignment. Dual extruder printers are generally more expensive.

3. Filament Mixing

Some advanced printers mix two or more filaments to produce custom gradients or colors.

- How it works: A single nozzle blends filaments dynamically during printing. The printer’s software controls the ratio of filaments to achieve smooth color transitions.

- Advantages: Great for creating gradients or unique color combinations. Minimal manual intervention required.

- Challenges: Complex setup and software requirements. Limited availability of compatible printers.

4. Painting Post-Printing

Painting allows for endless customization but requires effort after the print.

- How it works: Print the model in a neutral color like white. Paint the model using acrylics, airbrush, or other mediums.

- Advantages: No printer limitations; works with any 3D printer. Highly detailed results with artistic flexibility.

- Challenges: Time-consuming. Requires skill and patience for detailed results.

Tips for Successful Multicolor 3D Printing

1. Use Appropriate Software

3D printing software plays a vital role in multicolor projects. Tools like Cura, PrusaSlicer, and Simplify3D offer features to assign colors to specific parts of a model. Check for:

- Layer-based color changes.

- Multi-extruder support.

2. Model Preparation

Start with high-quality 3D models designed for multicolor printing. You can find such models on platforms like Thingiverse or create your own using CAD software. Split models into separate parts or assign colors using slicer tools.

3. Calibrate Your Printer

Calibrate your printer carefully to prevent color bleeding and misalignments, especially when using dual extruders.

Ensure nozzles are correctly aligned. Test print small multicolor objects to adjust settings.

4. Manage Filaments

Use quality filaments for consistent results. Store filaments properly to avoid moisture absorption, which can affect print quality.

5. Optimize Layer Heights

Smaller layer heights produce smoother transitions and finer details in multicolor prints. Balance this with increased print times.

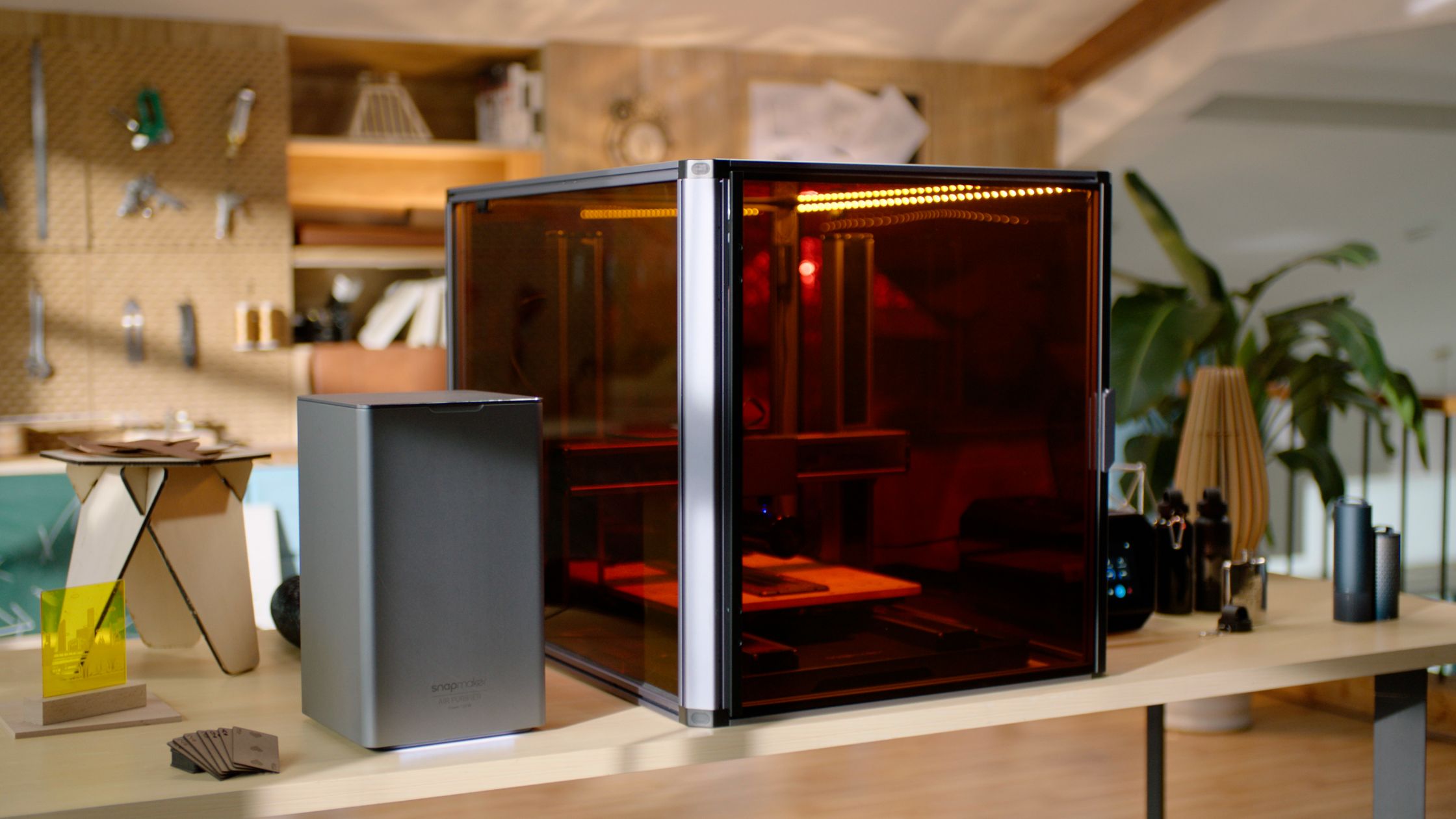

Choosing the Best 3D Printer for Multicolor Printing

The best 3D printers for multicolor printing offer features like dual extrusion, advanced filament management, and high precision. Consider these factors when selecting a printer:

- Extrusion Capabilities: Dual extruders or filament mixing support.

- Software Compatibility: Works with slicers optimized for multicolor prints.

- Build Volume: Ensures the printer can handle your project size.

- Ease of Use: Automatic filament loading/unloading and intuitive calibration.

Use Cases for Multicolor 3D Printing

1. Artistic Creations

From vibrant sculptures to decorative items, multicolor printing adds a professional finish to art projects.

2. Functional Prototypes

Color-coded prototypes help designers showcase multiple components or materials in a single print.

3. Educational Models

Multicolor prints enhance visual learning by creating models that differentiate elements clearly, such as in anatomical models.

4. Branding and Marketing

Businesses use multicolor prints for logos, promotional materials, and custom merchandise.

Conclusion

Mastering multicolor 3D printing opens a world of creative possibilities. Whether you’re manually swapping filaments or leveraging advanced dual-extrusion technology, the right techniques and tools can make your projects stand out. For optimal results, pair your approach with the best 3D printer that meets your needs. By combining thoughtful preparation and innovative methods, you can create stunning, multicolor models that showcase your creativity and technical skills.

Happy printing!