How SolidWorks Simulation and SolidWorks Electrical Enhance Product Design in Singapore

Designing modern products requires more than creativity—it demands precision, testing, and seamless integration between mechanical and electrical components. Engineers in Singapore are increasingly turning to SolidWorks Simulation and SolidWorks Electrical to meet these challenges efficiently. These tools allow teams to validate designs virtually while ensuring electrical and mechanical systems work together flawlessly.

Testing Designs Virtually with SolidWorks Simulation

SolidWorks Simulation empowers engineers to test their designs under real-world conditions without producing physical prototypes. Structural stress, thermal performance, vibration, and fluid dynamics can all be analyzed within the software. For Singapore-based companies, this means faster development cycles, reduced material waste, and lower production costs. Engineers can iterate quickly and make informed design decisions before committing to manufacturing.

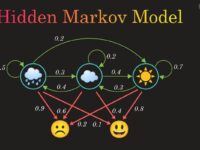

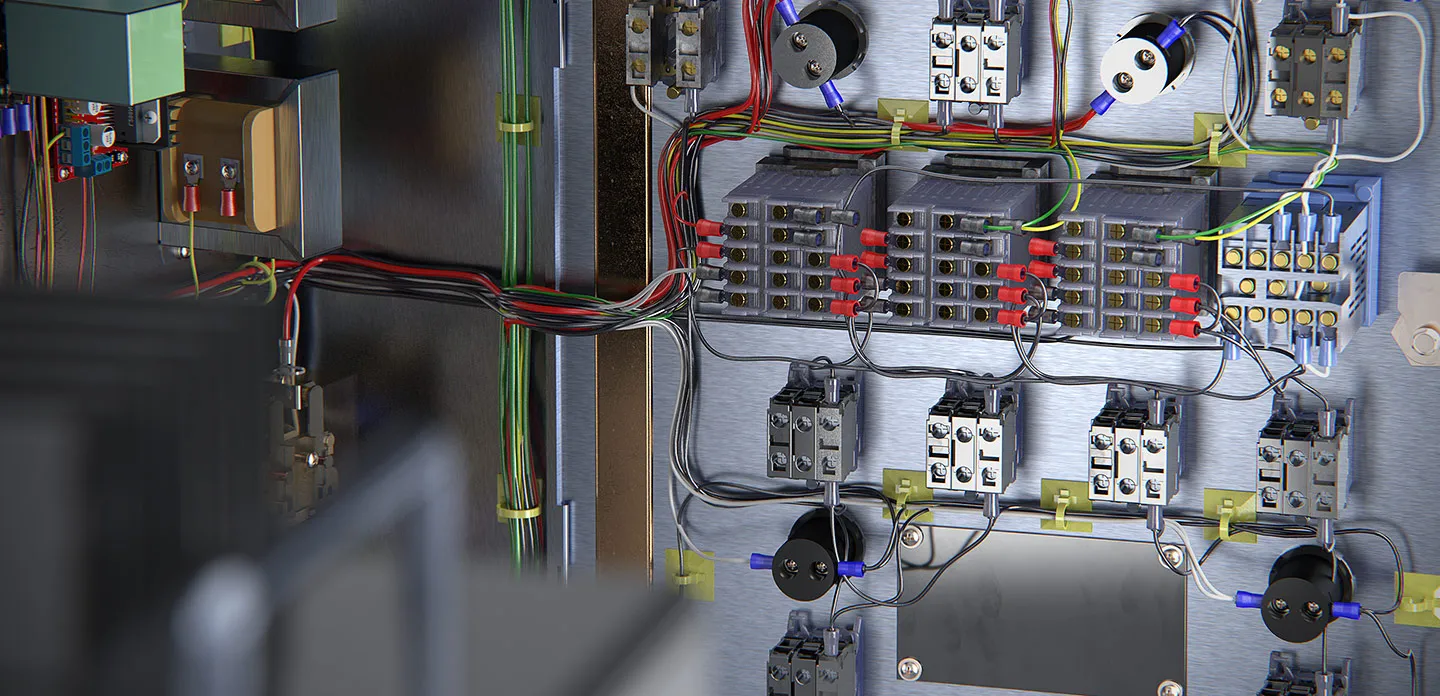

Integrating Electrical Systems Seamlessly

Modern products often rely heavily on electrical components, from sensors to wiring harnesses. SolidWorks Electrical allows engineers to design, document, and manage electrical systems efficiently. By integrating these designs with mechanical models, teams can detect clashes early, ensure proper routing, and maintain accurate documentation. This integration reduces errors and ensures smoother collaboration between mechanical and electrical engineers.

Improved Collaboration and Productivity

By combining SolidWorks Simulation and SolidWorks Electrical, Singapore engineers can work more collaboratively. Design validation, performance analysis, and electrical integration happen within a unified workflow. This reduces miscommunication, speeds up revisions, and ensures a more reliable final product.

Conclusion

For Singapore engineers, leveraging SolidWorks Simulation and SolidWorks Electrical means faster, more accurate, and better-integrated product development. These tools help teams optimize designs, reduce errors, and deliver high-quality products efficiently.