Navigating Reverse Logistics Challenges: Strategies for Efficient Returns Management

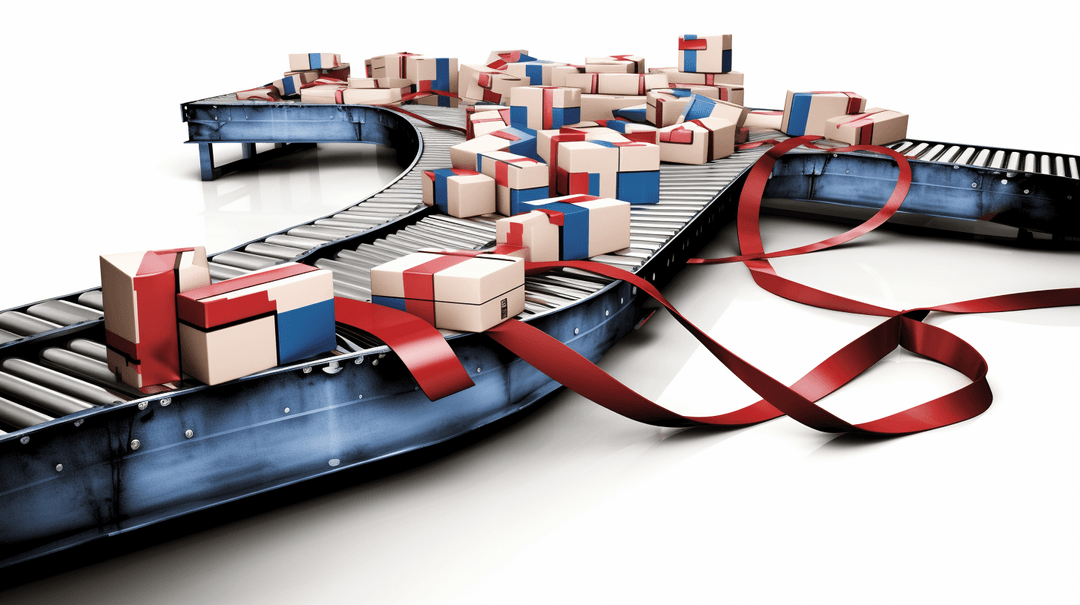

Reverse logistics has become a critical component of modern supply chains, particularly with the rise of e-commerce and increased customer expectations. Unlike traditional logistics, which focuses on the movement of goods from suppliers to customers, reverse logistics involves the process of moving products back from consumers to manufacturers, distributors, or recycling centers. While reverse logistics can enhance sustainability, customer satisfaction, and cost recovery, it presents unique challenges that organizations must address to optimize efficiency and profitability.

Understanding Reverse Logistics Challenges

Reverse logistics challenges stem from the inherent complexity of handling returned or end-of-life products. Unlike forward logistics, where products follow a predictable path, reverse logistics involves unpredictable volumes, varied conditions of returned items, and multiple handling points. Each product returned may require inspection, sorting, repackaging, refurbishment, recycling, or disposal.

One major challenge is the unpredictability of return volumes. Customer returns can fluctuate significantly due to seasonal demand, promotions, or product defects. Managing inventory for reverse logistics requires flexibility in storage, labor allocation, and transportation capacity. Companies that fail to anticipate these fluctuations may face congestion, increased handling costs, and delayed processing.

Another challenge lies in product condition and quality assessment. Returned items may be damaged, incomplete, or otherwise unsuitable for resale. Assessing each item’s condition accurately is labor-intensive and requires trained personnel. Incorrect evaluation can lead to either unnecessary disposal of salvageable products or the accidental redistribution of defective items, both of which affect profitability and brand reputation.

Transportation and routing complexities also pose challenges. Reverse logistics often involves multiple touchpoints, including local return centers, regional hubs, and final processing facilities. Coordinating transportation efficiently while minimizing costs and transit time is difficult, especially when returns are sporadic or originate from widely dispersed locations.

Additionally, reverse logistics involves compliance with environmental and regulatory standards. Products containing hazardous materials, electronics, or restricted items require special handling, recycling, or disposal processes. Failure to adhere to regulations can result in fines, reputational damage, and legal complications.

Operational and Financial Implications

Reverse logistics challenges have significant operational and financial implications. Inefficient returns processing increases labor, storage, and transportation costs. Prolonged return cycles delay revenue recovery and impact working capital. Businesses may also face increased customer dissatisfaction if returns are handled slowly or inaccurately, undermining trust and loyalty.

Inventory management becomes more complicated in reverse logistics. Companies must track returned items, segregate them based on condition, and update stock records in real-time. Without accurate data, organizations risk inventory inaccuracies, stockouts, or overstocking, which further drives up operational costs.

Returns also affect sustainability objectives. Improper disposal or inefficient handling increases waste, carbon emissions, and resource consumption. For organizations pursuing environmental responsibility, addressing reverse logistics challenges is essential to achieve corporate sustainability goals while minimizing the environmental footprint of returned goods.

Strategies to Overcome Reverse Logistics Challenges

Addressing reverse logistics challenges requires a combination of process optimization, technology adoption, and strategic planning. Organizations can implement several strategies to streamline returns management and improve overall efficiency.

Implementing automated returns management systems helps track and manage the flow of returned products. These systems provide real-time visibility into return status, item condition, and inventory updates. By reducing manual processing, companies can minimize errors, accelerate processing times, and make more informed decisions regarding refurbishment, resale, or disposal.

Segmentation of returns is another effective strategy. Categorizing returns based on condition, product type, and destination allows organizations to prioritize handling and apply appropriate processing methods. This approach ensures that high-value or easily resalable items are processed quickly, while damaged or hazardous items receive specialized attention.

Optimizing transportation and routing reduces costs and improves efficiency. Consolidating returns, planning efficient pickup routes, and leveraging regional hubs can minimize transit distances and reduce fuel consumption. Partnerships with third-party logistics providers experienced in reverse logistics can also provide scalable solutions for managing unpredictable return volumes.

Employee training and standard operating procedures are essential to overcome challenges related to inspection and quality assessment. Clear guidelines for evaluating returned products ensure consistency and accuracy, minimizing errors and protecting brand reputation. Regular training ensures that personnel remain skilled in handling new product lines and compliance requirements.

Sustainability-focused approaches help organizations address environmental and regulatory challenges. Recycling programs, refurbishment initiatives, and eco-friendly disposal methods reduce waste and align reverse logistics processes with corporate social responsibility goals. Partnering with certified recycling or waste management providers ensures compliance with relevant regulations and supports long-term environmental objectives.

Long-Term Benefits of Addressing Reverse Logistics Challenges

Effectively managing reverse logistics challenges offers significant long-term benefits. Improved returns processing increases operational efficiency, reduces costs, and accelerates revenue recovery. Streamlined systems and accurate inventory management enhance decision-making, allowing businesses to respond proactively to market trends and customer demands.

Enhanced customer satisfaction is another critical benefit. A smooth, transparent, and efficient returns process strengthens customer trust and loyalty, providing a competitive advantage in industries where returns are common. Satisfied customers are more likely to make repeat purchases and recommend the brand, contributing to overall growth and profitability.

Sustainability and compliance improvements also result from optimized reverse logistics. Responsible handling of returned products reduces environmental impact, supports regulatory adherence, and demonstrates corporate responsibility. This not only benefits the planet but also enhances brand reputation and stakeholder confidence.

Ultimately, addressing reverse logistics challenges transforms a traditionally costly and complex process into a strategic advantage. Companies that invest in technology, process improvement, and employee training can reduce inefficiencies, recover value from returned products, and maintain strong relationships with both customers and regulators. By turning challenges into opportunities, reverse logistics becomes an integral part of a resilient and efficient supply chain.