Streamline Your Production: Top Benefits of Automated Inspection Systems in Industry

In today’s fast-paced industrial landscape, efficiency and precision are paramount. Automtaed Inspection systems have emerged as a game-changer, revolutionizing how industries maintain quality and streamline production. These advanced systems offer numerous benefits, ensuring that businesses stay competitive and meet the ever-increasing demands of the market.

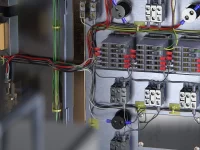

Enhanced Quality Control

Automated inspection systems provide unparalleled accuracy in detecting defects and inconsistencies. Unlike manual inspections, which are prone to human error, computerized systems use sophisticated technologies such as machine vision, artificial intelligence, and sensors to perform thorough and precise inspections. This leads to a significant reduction in defective products, enhancing overall product quality and customer satisfaction.

Increased Production Speed

One of the most significant advantages of automated inspection is the boost in production speed. Computerized systems can inspect products at a much faster rate than human inspectors, allowing for continuous and rapid production without compromising quality. This efficiency helps industries meet tight deadlines and increase their output, leading to higher profitability.

Cost Savings

Investing in automated inspection systems can lead to substantial cost savings in the long run. By reducing the number of defective products, companies can minimize waste and avoid the costs associated with product recalls and rework. Additionally, automated systems require less labor for inspection tasks, freeing up human resources for more critical functions within the organization.

Consistency and Reliability

Automated inspection systems ensure consistent and reliable results. These systems operate with the same level of precision and accuracy every time, eliminating the variability inherent in manual inspections. This consistency is crucial for industries that require adherence to strict quality standards and regulatory compliance.

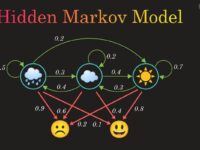

Data Collection and Analysis

Automated inspection systems are equipped with advanced data collection and analysis capabilities. They can capture detailed information about each inspected item, providing valuable insights into production processes and potential areas for improvement. This data-driven approach enables businesses to make informed decisions, optimize their operations, and maintain a competitive edge.

Improved Worker Safety

Incorporating automated inspection systems can significantly enhance worker safety. By taking over repetitive and potentially hazardous inspection tasks, these systems reduce the risk of workplace injuries. This not only protects employees but also contributes to a safer and more productive work environment.

Flexibility and Scalability

Automated inspection systems are highly flexible and scalable, making them suitable for a wide range of industries and applications. They can be easily adapted to different production lines and inspection requirements, providing a versatile solution for businesses looking to enhance their quality control processes.

Conclusion

Incorporating automated inspection systems into industrial production processes offers a myriad of benefits, from enhanced quality control and increased production speed to cost savings and improved worker safety. These systems are a valuable investment for any industry seeking to streamline production and maintain a competitive edge. By leveraging the power of automated inspection systems, businesses can ensure consistent quality, optimize operations, and drive long-term success.